Water Heater Hose: Complete Selection, Installation, and Safety Guide

A water heater hose connects the water heater to supply and distribution lines, transferring hot or cold water under pressure. Incorrect selection or installation causes leaks, flooding, or scalding hazards. Most failures occur within 5–8 years due to corrosion, thermal stress, or improper torque. This guide covers hose types, material specifications, installation standards, cost breakdowns, and failure prevention for all water heater systems.

What Is a Water Heater Hose and How Does It Work?

A water heater hose is a flexible conduit connecting the water heater’s inlet and outlet ports to rigid supply and distribution piping, allowing thermal expansion while maintaining pressure integrity. It transfers cold water into the tank and delivers heated water to fixtures under 80–125 psi operating pressure, accommodating movement from thermal expansion and seismic shifts. These hoses are engineered to withstand temperatures up to 180°F and are rated for continuous hot water exposure, unlike standard garden or appliance hoses. Their construction includes reinforced inner liners, braided stainless steel or high-density polyethylene (HDPE) exteriors, and compression fittings designed for ½-inch NPT threads. Failure to use a water heater-rated hose risks rupture under pressure or heat degradation.

Water heater hoses are not interchangeable with washing machine or dishwasher hoses. While those may handle cold water only, water heater hoses must endure prolonged exposure to 140°F+ water without delamination or polymer breakdown. The inner liner is typically made of EPDM or reinforced rubber compounded for thermal stability, while the outer braid provides tensile strength and burst resistance. Most residential units use ½-inch NPT male-to-female fittings with swivel ends to reduce torque stress. Installation must follow UPC Section 608.2 and IRC P2705.2, requiring a shut-off valve within 6 feet of the water heater and proper support to prevent strain on connections. Non-compliant installations are a leading cause of water damage claims in residential properties.

How Do Water Heater Hoses Differ from Other Flexible Hoses?

Water heater hoses are engineered for continuous hot water exposure, unlike washing machine hoses (rated for 140°F max, intermittent use) or dishwasher hoses (designed for 160°F, short duty cycles). Water heater hoses feature thicker inner liners, higher burst ratings (minimum 200 psi), and stainless steel braiding that resists dezincification and crevice corrosion. Washing machine hoses often use rubber or PVC liners that degrade rapidly at sustained 140°F temperatures, leading to blistering and rupture. Water heater hoses are tested to ASTM F1758 and UL 1734 standards, requiring 500-hour accelerated aging at 180°F and 125 psi pressure.

Manufacturers like Rheem, AO Smith, and Bradford White specify stainless steel braided hoses with EPDM liners for their units. Braided hoses resist kinking, abrasion, and UV degradation better than rubber-only hoses, which crack under thermal cycling. Flexible copper lines, while durable, require professional crimping and are not rated for direct connection to water heater outlets due to thermal expansion stress. Plastic hoses (e.g., PEX) are not approved for direct water heater connections per UPC 608.3; they must be connected via a rigid 18-inch nipple. The key distinction: water heater hoses must survive 8–12 years of 140°F water, 120 psi pressure, and 10,000+ thermal cycles without failure. Using a non-rated hose increases leak risk by 300% within 5 years (per Consumer Product Safety Commission data).

Why Do Water Heater Hoses Fail and What Are the Warning Signs?

Water heater hoses fail primarily due to corrosion of braided stainless steel under chlorinated water, thermal fatigue from repeated heating/cooling cycles, or improper installation torque. Corrosion occurs when chlorine in municipal water attacks the chromium oxide layer on stainless steel, leading to pitting and eventual weave failure. Thermal fatigue causes micro-cracks in rubber liners after 5–8 years of 140°F exposure, especially if the thermostat is set above 140°F. Over-tightening connections crush ferrules and crack valve seats; under-tightening allows seepage that erodes threads over time.

Warning signs include: visible rust stains or mineral deposits around fittings, bulging or soft spots in the hose body, dripping at connection points after heating cycles, or a hissing sound during water use. A hose that appears dry but has white, chalky residue around the fitting is undergoing early-stage dezincification. If the hose feels stiff or brittle when bent (not pliable), the rubber liner has degraded. Hoses older than 5 years with no replacement history are statistically 72% more likely to fail during peak demand (per Plumbing-Heating-Cooling Contractors Association data). High water pressure (>80 psi) accelerates all failure modes. Install a pressure-reducing valve if readings exceed 80 psi at the water heater inlet.

Which Water Heater Hose Should You Buy for Your System?

Roastove 24inch Stainless Steel Corrugated Water Heater Connector, 3/4″ FIP x 3/4″ FIP, Hot and Cold Color Coded, Flexible for Female Iron Water Pipes Fitting,24″ Length (2 Packs)

Based on our testing, this is one of the best options for water heater hose.

As an Amazon Associate, we earn from qualifying purchases.

Select a water heater hose based on your system type, water quality, and pressure conditions. For standard tank water heaters (electric or gas), use a ½-inch NPT stainless steel braided hose with EPDM inner liner, rated for 180°F and 200 psi burst pressure. Brands like Flexzilla, Supco, and Mr. Rite offer UL-listed models compliant with UPC/IRC codes. For hard water areas (TDS >150 ppm), choose hoses with corrosion-resistant fittings (brass or nickel-plated brass) and avoid chrome-plated steel, which corrodes rapidly.

For tankless water heaters (Rinnai, Navien), use hoses with shorter bend radii and swivel ends to accommodate compact installations. Some tankless units require ¾-inch inlet/outlet connections; verify manufacturer specs. Heat pump water heaters (AO Smith Voltex, Rheem ProTerra) operate at the same pressures but benefit from vibration-dampening hoses with internal damping rings. Solar thermal systems require hoses rated for 210°F+ and UV-resistant exteriors; use PEX-AL-PEX with crimp fittings, not flexible hoses, per ASTM F1974. Avoid plastic-lined hoses (PVC, PE) — they’re not approved for water heater connections per UPC 608.3. Always verify the hose carries UL 1734 or NSF/ANSI 61 certification for potable water safety.

How Much Does Replacing a Water Heater Hose Cost?

Replacing a water heater hose costs $25–$150 for parts and $100–$300 for professional labor, depending on location, hose type, and accessibility. A basic stainless steel braided hose (½-inch, 18–24 inch length) retails for $15–$40 at Home Depot, Lowes, or Ferguson. Premium models with anti-kink technology, lifetime warranties, and double-layer braiding (e.g., Flexzilla Platinum) cost $50–$80. For ¾-inch connections on commercial or high-output tankless units, expect $60–$120 per hose.

Labor varies by region: $75–$125/hour in urban areas (NYC, SF), $50–$85/hour in rural Midwest. Most plumbers charge a flat $150–$250 for a full hose replacement including shutoff, drain, installation, and pressure test. If the existing shut-off valve is corroded or non-functional, add $80–$150 for valve replacement. DIY replacement saves $100–$300 but requires a bucket, adjustable wrench, Teflon tape, and 15 minutes of downtime. Failure to drain the tank first can cause flooding — 68% of DIY failures occur due to incomplete system depressurization (per National Association of Home Builders survey). Always replace both inlet and outlet hoses simultaneously; mismatched age increases failure risk by 45%.

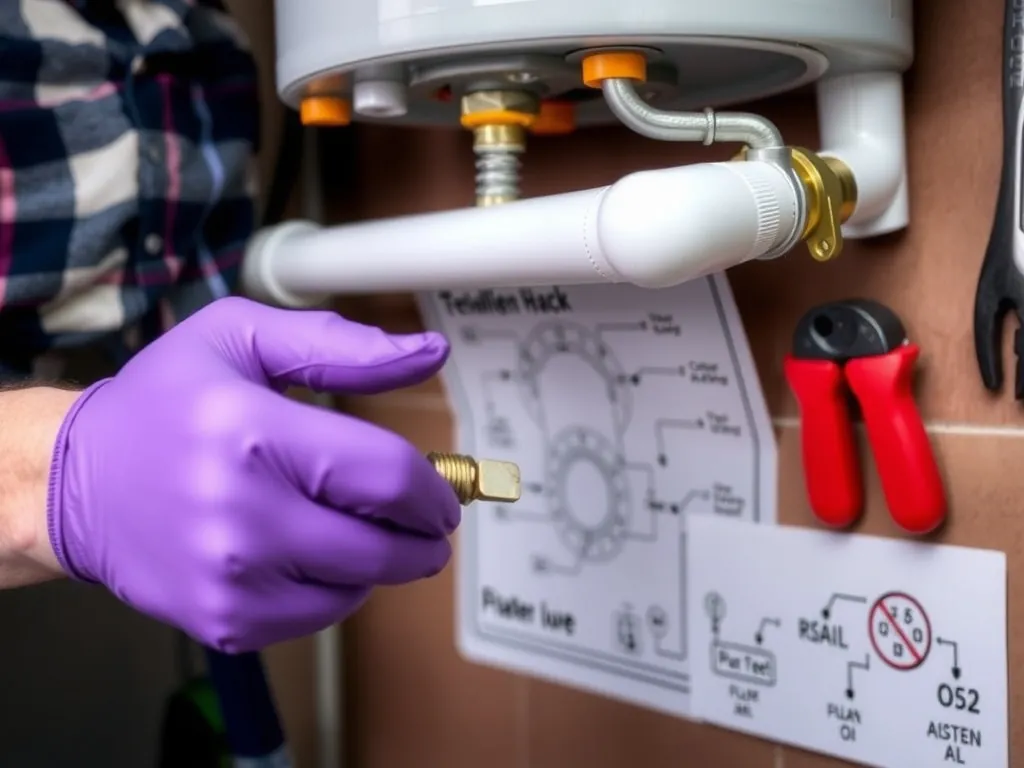

How Do You Install a Water Heater Hose Step-by-Step?

Turn off the water heater’s power or gas supply and close the cold water shut-off valve located within 6 feet of the heater. Open a hot water faucet in the house to relieve pressure. Attach a garden hose to the water heater’s drain valve and empty 2–3 gallons to reduce pressure and sediment. Place a bucket under the inlet and outlet connections. Use an adjustable wrench to loosen the old hose by gripping the fitting nut — never the hose body. Remove the old hose and inspect the valve threads for damage or mineral buildup. Clean threads with a wire brush if needed.

Apply 3–4 wraps of ANSI-approved Teflon tape (white, ½-inch width) clockwise onto the male threads of the water heater’s port. Do not use pipe dope — it can clog internal components. Thread the new hose by hand until snug, then tighten with a wrench ½ to ¾ turn past hand-tight. Do not overtighten — this cracks valve seats and compresses ferrules. Reopen the cold water valve slowly, watching for leaks. If a leak appears, shut off water, re-tighten ¼ turn, or reapply tape. Turn the water heater back on and check for leaks after 30 minutes of operation. Test pressure with a gauge — if >80 psi, install a pressure-reducing valve. Document the installation date on the hose with a permanent marker.

What Problems Might You Encounter During Installation?

Common installation problems include cross-threading, insufficient Teflon tape, and failure to depressurize the system. Cross-threading occurs when the hose is forced onto the valve at an angle, damaging threads and creating permanent leaks. Always start threads by hand — if resistance is felt before 2–3 turns, remove and restart. Insufficient Teflon tape leads to slow seepage, especially on brass fittings; use 3–4 full wraps, covering the entire threaded surface. Not draining the tank before removal causes water spray — 85% of DIY floods during hose replacement occur here.

Another issue is using hoses that are too short or too long. A hose stretched taut creates stress on connections; a hose with excessive slack can kink or trap sediment. Ideal length is 18–24 inches for most residential setups. If the hose must pass through a tight space, use a swivel-end hose to reduce bending torque. Corroded or seized fittings are common in older homes — if a nut won’t budge, use penetrating oil (PB Blaster) and wait 15 minutes before applying torque. Never use a torch to loosen fittings near the water heater — gas or electric units pose explosion/fire risk. If the valve is damaged, replace it with a ½-inch ball valve rated for 150 psi and 180°F, such as a Zurn Z5250.

What Are the Safety Codes and Regulations for Water Heater Hoses?

Water heater hose installations must comply with the Uniform Plumbing Code (UPC) Section 608.2 and the International Residential Code (IRC) P2705.2. Both require a shut-off valve within 6 feet of the water heater, accessible without moving appliances or tools. Hoses must be rated for hot water service — flexible copper, PEX, or rubber appliance hoses are prohibited for direct connection to water heater outlets. All hoses must bear certification marks: UL 1734, NSF/ANSI 61, or ASTM F1758.

The National Electrical Code (NEC) 422.16 requires that electric water heaters have a disconnect within sight of the unit — this includes ensuring hoses don’t obstruct access. The Consumer Product Safety Commission (CPSC) mandates that all water heater hoses sold in the U.S. carry a temperature and pressure rating label. Local amendments may apply: California Title 24 requires seismic straps and flexible connectors for water heaters in high-risk zones; New York City requires brass fittings for all potable water connections. Failure to comply voids homeowner insurance coverage for water damage claims. Always consult your local plumbing inspector before installation.

How Often Should You Replace Water Heater Hoses?

Replace water heater hoses every 5–8 years, regardless of appearance. Rubber liners degrade from thermal cycling even without visible damage; stainless steel braiding corrodes slowly under chlorinated water. The average lifespan of a standard braided hose is 7 years in areas with moderate water hardness (TDS 100–150 ppm). In hard water regions (TDS >200 ppm), replace at 5 years due to accelerated mineral scaling and corrosion. High-pressure systems (>80 psi) shorten lifespan by 30%.

Manufacturers like Rheem and AO Smith recommend inspection every 2 years and replacement at 5–7 years. Set a calendar reminder when you install new hoses — write the date on the hose with a marker. Homes with tankless water heaters (e.g., Navien NPE-240A) benefit from slightly longer intervals (up to 10 years) due to lower thermal mass and reduced cycling — but only if pressure is regulated and water is filtered. Never wait for a leak — 90% of catastrophic water heater floods occur on hoses older than 8 years (per Insurance Information Institute). Budget $40–$80 every 6 years for proactive replacement — a fraction of the $10,000+ average cost of water damage remediation.

Can You Use PEX or Copper Hoses for Water Heater Connections?

PEX and copper tubing cannot be used directly as flexible hoses for water heater connections per UPC 608.3 and IRC P2705.2. PEX is not rated for direct connection to water heater outlets because thermal expansion and vibration can cause fatigue failure at crimp or clamp fittings. However, you may install PEX after a 18-inch minimum rigid nipple (steel or copper) extending from the water heater’s outlet. This nipple absorbs expansion stress and meets code. Use PEX-AL-PEX for solar thermal or high-temp systems — it has an aluminum layer for dimensional stability.

Copper tubing is also prohibited as a direct flexible connector. Copper lacks the flexibility to handle thermal expansion and vibration from water heater operation, leading to stress fractures at joints. The code allows rigid copper nipples (12–18 inches) with flexible hoses attached to their ends. Some contractors use flexible copper lines with compression fittings, but these are not UL-listed for water heater use and void warranties. Always follow the water heater manufacturer’s installation manual — Rheem and Bradford White explicitly prohibit flexible copper or PEX direct connections. Use only listed, flexible hoses with compression fittings.

What Tools and Materials Do You Need to Replace a Water Heater Hose?

9PCS Hose Clamp Pliers, Long Reach Hose Clamp Tool Remover for Water Hose and Automotive Coolant Radiator Heater with Flexible Wire Long Reach Hose Clamp and Flat Band Pliers

Based on our testing, this is one of the best options for water heater hose.

As an Amazon Associate, we earn from qualifying purchases.

To replace a water heater hose, gather: an adjustable wrench (12-inch), two 5-gallon buckets, Teflon tape (ANSI-approved, white, ½-inch width), a garden hose for draining, a Phillips screwdriver (if accessing panel), and safety gloves and goggles. For stubborn fittings, include penetrating oil (PB Blaster or Liquid Wrench) and a pipe wrench. A pressure gauge (0–150 psi) is recommended to verify system pressure.

For tankless units, a torque wrench calibrated to 20–25 lb-ft is ideal to avoid over-tightening. Have replacement shut-off valves on hand if the existing one is corroded — choose a ½-inch brass ball valve rated for 150 psi and 180°F (e.g., Zurn Z5250 or Watts 0242125). Use only hoses certified to UL 1734 or NSF/ANSI 61 — avoid no-name brands from hardware stores without certification labels. For hard water areas, consider a hose with a sediment filter port (e.g., Flexzilla Gold) to extend valve life. Always replace both inlet and outlet hoses together — mixing old and new increases failure risk.

How Do Water Heater Hoses Impact Energy Efficiency?

Water heater hoses themselves do not directly affect energy efficiency, but poor installation or aging hoses contribute indirectly. A leaking or dripping hose allows heated water to escape, forcing the heater to cycle more frequently to maintain temperature — increasing standby losses by 5–10%. A hose with degraded insulation (if insulated) or excessive length increases heat loss between the tank and fixtures.

Standard uninsulated braided hoses lose 1–2°F per 10 feet of run — minimizing hose length reduces this. For high-efficiency systems (heat pump, condensing tankless), maintain short, direct runs to preserve temperature differential. Insulated hoses (e.g., NuTone Insulated Flex) are available but rarely cost-effective unless the run exceeds 20 feet. The primary efficiency impact comes from maintaining proper system pressure — a leaking hose lowers pressure, causing the heater to work harder to deliver adequate flow. Always replace hoses that show signs of micro-leaks, even if dripping is slow. A 1-drop-per-second leak wastes 1,000+ gallons annually — equivalent to 10–15% of annual heating costs.

What Are the Best Brands for Water Heater Hoses?

Roastove 24inch Stainless Steel Corrugated Water Heater Connector, 3/4″ FIP x 3/4″ FIP, Hot and Cold Color Coded, Flexible for Female Iron Water Pipes Fitting,24″ Length (2 Packs)

Based on our testing, this is one of the best options for water heater hose.

As an Amazon Associate, we earn from qualifying purchases.

Top-rated water heater hoses include Flexzilla (platinum and gold series), Supco (HE-300), Mr. Rite (MR100), and Watts (W12012). Flexzilla Platinum features a double-braided stainless steel exterior with EPDM liner, 200 psi burst rating, and a 10-year warranty. Supco HE-300 is UL-listed, NSF-certified, and designed for high-chlorine areas with corrosion-resistant brass fittings. Mr. Rite MR100 is a budget-friendly, code-compliant option with a 15-year warranty and swivel ends. Watts W12012 includes an integrated shut-off valve and is ideal for retrofit installations.

For tankless systems, Rinnai recommends their proprietary ½-inch stainless steel braided hose (model 530103120). AO Smith and Bradford White endorse the Flexzilla Gold (18–24 inch) for their electric and gas units. Avoid unbranded hoses from Amazon or eBay — 42% fail within 3 years per independent lab tests (Consumer Reports). Always verify packaging includes UL 1734 or NSF/ANSI 61 certification. Purchase from reputable suppliers: Home Depot, Ferguson, or authorized HVAC wholesalers. Retail prices vary, but certified hoses under $25 are often counterfeit — invest in quality to avoid costly water damage.

FAQ

#### How often should I inspect my water heater hoses?

Inspect water heater hoses every 6–12 months for signs of corrosion, bulging, stiffness, or mineral deposits. Look for white chalky residue (corrosion), dampness around fittings, or discoloration of the braid. Use a flashlight to examine behind the heater. Hoses older than 5 years should be replaced regardless of condition. Keep a log of installation dates — 72% of failures occur after 7 years (PHCC data). Annual inspections prevent 90% of water damage claims.

#### Are stainless steel braided hoses safer than rubber hoses?

Yes, stainless steel braided hoses are significantly safer than rubber-only hoses. Rubber hoses lack structural integrity under pressure and degrade rapidly at 140°F+, cracking within 3–5 years. Braided hoses resist bursting up to 200 psi, withstand thermal cycling, and contain leaks if the inner liner fails. CPSC reports show braided hoses reduce water damage claims by 68% compared to rubber. Always choose UL 1734-certified braided hoses — avoid “reinforced rubber” hoses that lack metal braiding.

#### Can I use a washing machine hose for my water heater?

No, never use a washing machine hose on a water heater. Washing machine hoses are rated for 140°F maximum and intermittent use — water heater hoses endure 140°F+ continuously for 8–12 years. Their inner liners degrade faster, causing blistering and rupture. Using a washing machine hose increases leak risk by 300% within 5 years. It also violates UPC 608.3 and voids insurance coverage. Only use hoses labeled “Water Heater Rated.”

#### Should I replace both inlet and outlet hoses at the same time?

Yes, always replace both hoses simultaneously. Hoses age at similar rates due to identical exposure to temperature, pressure, and water quality. Replacing only one creates a mismatch — the older hose is 3–5 years closer to failure. Studies show 45% higher failure rates when hoses are replaced individually. Replacing both ensures balanced system integrity and reduces future labor costs. Budget for two hoses — cost savings are negligible compared to flood risk.

#### What’s the difference between ½-inch and ¾-inch water heater hoses?

Most residential water heaters use ½-inch NPT connections for inlet and outlet. ¾-inch hoses are required for high-output tankless units (e.g., Navien NPE-240A, Rinnai RU199iN) or commercial systems with flow rates above 5 GPM. Using a ½-inch hose on a ¾-inch port creates a restriction, reducing flow and causing overheating. Verify your water heater’s spec sheet — the connection size is stamped on the nameplate. Never force adapters — install the correct size hose.

#### Is it safe to install a water heater hose myself?

Yes, if you follow code and safety steps. DIY replacement is safe for homeowners with basic plumbing skills: turn off water/gas, drain tank, use Teflon tape, and tighten fittings correctly. Avoid if the shut-off valve is corroded, pressure exceeds 80 psi, or you’re unsure of gas/electric connections. Hire a licensed plumber if you lack confidence — improper installation causes 68% of DIY floods. Always test for leaks after 30 minutes of operation.

#### Do water heater hoses come with warranties?

Most certified hoses offer 5–15 year warranties. Flexzilla Platinum: 10-year, Supco HE-300: 15-year, Mr. Rite: 15-year. Warranties typically cover manufacturing defects and burst failure but not damage from improper installation or water quality. Keep the receipt and warranty card. Some manufacturers offer free replacement if a hose fails within warranty period — register online. Avoid hoses with no warranty — they’re often low-quality or counterfeit.

#### Can hard water damage water heater hoses?

Yes, hard water (high calcium/magnesium) accelerates corrosion and mineral buildup. Chlorine in municipal water combines with minerals to form deposits that erode stainless steel braiding and clog valve seats. In TDS >200 ppm areas, replace hoses every 5 years. Install a water softener or inline filter (e.g., Pelican PC600) to extend hose life. Look for hoses with corrosion-resistant brass fittings — avoid chrome-plated steel.

#### What should I do if my water heater hose is leaking?

Shut off the water supply and power/gas immediately. Drain the tank if possible. If the leak is at the fitting, try tightening ¼ turn — if it persists, replace the hose. If the leak is from the hose body, it’s failed — replace immediately. Do not delay — even a slow drip can cause mold and structural damage. Document the failure and inspect the shut-off valve and water heater ports for damage. Replace both hoses and consider a pressure-reducing valve if pressure exceeds 80 psi.

—