Top Water Heater Circulation Pump Recommendations

Based on extensive research and customer reviews, here are the top-rated water heater circulation pump products available on Amazon. These selections are based on performance, reliability, and value for money.

Disclosure: This post contains affiliate links. If you purchase through these links, we may earn a commission at no additional cost to you.

Water Heater Circulation Pump: Complete Guide to Selection, Installation, and Optimization

A water heater circulation pump eliminates wait time for hot water by continuously circulating heated water through plumbing pipes, reducing waste and improving efficiency. Systems typically save 10,000–15,000 gallons of water annually in a four-person household and reduce energy use by 8–15% when paired with insulation and controls. This guide covers how circulation pumps work, types available, installation methods, cost analysis, troubleshooting, and code-compliant optimization for all water heater types.

What Is a Water Heater Circulation Pump and How Does It Work?

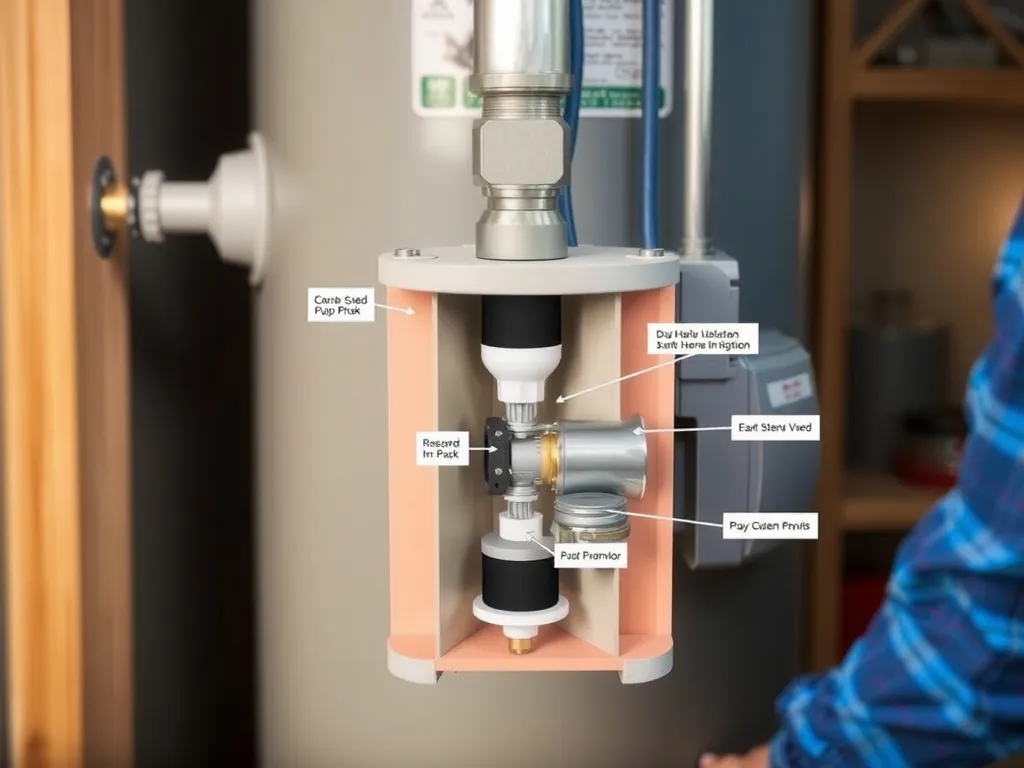

A water heater circulation pump actively moves hot water from the water heater through supply lines and back via a dedicated return line or crossover valve to maintain instant hot water at fixtures. The pump operates on demand or a timer, controlled by temperature sensors or user settings, and reduces water waste by eliminating the need to run taps while waiting. Modern systems integrate with tankless, storage tank, heat pump, and solar water heaters using compatible flow rates and pressure tolerances.

Circulation pumps use impeller-driven motors to generate flow between 1–5 gallons per minute (GPM), depending on system design and pipe length. In a standard recirculation loop, hot water travels from the heater to the farthest fixture, then returns through a dedicated ¾-inch return line to the heater’s inlet or cold water supply. Without a return line, a “crossover” system uses a thermostatic valve at the furthest fixture to allow hot water to backflow into the cold line when temperature drops below a set point—typically 95–105°F.

Pump operation is managed by one of three control methods: timer-based, thermostat-controlled, or demand-activated. Timer models run during peak usage hours (e.g., 6–9 AM and 5–9 PM), reducing runtime and energy use. Thermostat-controlled pumps activate when return-line water cools below a threshold. Demand systems use push-button or motion-sensor activation, providing hot water only when needed—ideal for low-occupancy homes.

Properly sized pumps match the home’s hydraulic resistance (measured in feet of head) and total pipe length. A typical residential system with 100 feet of piping and 10 elbows requires a pump with 3–5 feet of head capacity. Oversized pumps cause noise, pipe erosion, and excessive energy use; undersized units fail to deliver consistent temperatures. Always consult pump performance curves from manufacturers like Grundfos, Taco, or Uponor.

Grundfos and Taco Comfort Solutions provide detailed engineering specs for residential recirculation systems, including flow/pressure charts and compatibility with various water heater brands such as Rheem, AO Smith, and Navien.

How Do You Choose the Right Type of Water Heater Circulation Pump?

The right circulation pump depends on plumbing layout, water heater type, household usage patterns, and energy goals. The three primary types are full-loop (dedicated return), crossover (under-sink valve), and demand-initiated (on-demand) systems, each suited to specific configurations and retrofit feasibility.

Full-loop systems require a dedicated return pipe running from the farthest fixture back to the water heater. This design maintains complete separation between hot and cold lines, preventing temperature mixing. It’s most efficient but costly to install in existing homes—requiring major retrofitting. Ideal for new construction or whole-house renovations, full-loop setups work with all water heater types and support multi-zone configurations using zone valves.

Crossover systems, also called “California-style” recirculation, use a thermostatic mixing valve installed under the sink farthest from the heater. When hot water in the line cools below the set temperature (usually 95–105°F), the valve opens, allowing hot water to flow into the cold line until the loop reheats. This avoids the need for a return pipe but can slightly warm cold water, especially in long runs. Best for retrofitting older homes with single-point access.

Demand-initiated systems use motion sensors, push buttons, or smart controls to activate the pump only when hot water is needed. A user presses a button or walks into the bathroom, triggering the pump for 10–15 minutes. These systems waste no water and consume minimal electricity—typically 20–50 watts during operation. Models like the Grundfos Hot Water Recirculating System with demand control reduce annual energy use by up to 30% compared to continuous operation.

Tankless water heaters require compatible pumps that match flow activation thresholds. Most tankless units need a minimum flow rate of 0.5–0.7 GPM to ignite; circulation pumps must exceed this to avoid short-cycling. Use pumps labeled “tankless-compatible” such as the Taco D’MAND Series or Grundfos COMFORT System. Heat pump water heaters (HPWHs) benefit from recirculation but require lower pump speeds to avoid disrupting condensate drainage or compressor cycles.

Pump materials matter: bronze or stainless steel housings resist corrosion in hard water areas. Seals should be EPDM or Viton-rated for longevity. Motor efficiency ratings (MEI) above 0.7 indicate high-efficiency models compliant with DOE standards.

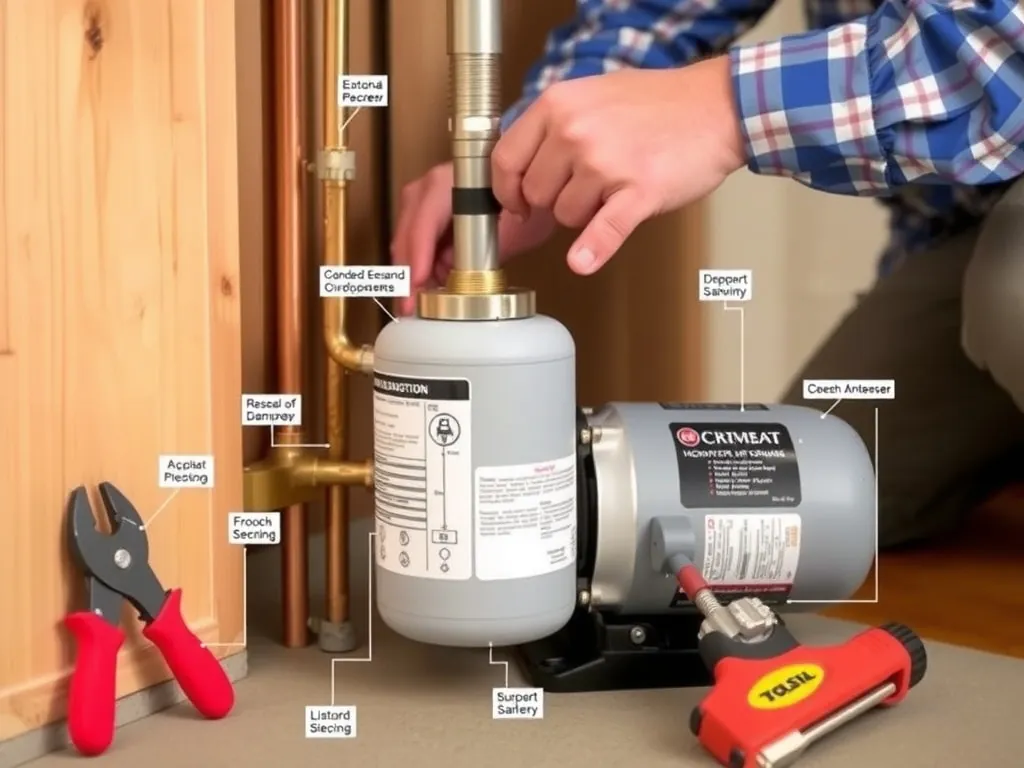

How Do You Install a Water Heater Circulation Pump Step-by-Step?

Installing a water heater circulation pump requires electrical, plumbing, and code compliance knowledge. The process varies by system type—dedicated return, crossover, or demand-activated—but follows core steps: shut off utilities, mount the pump, connect piping, wire controls, and test operation.

For a full-loop system with a dedicated return line:

1. Shut off power and water supply to the water heater. Turn off the circuit breaker for electric models or gas shutoff valve. Close the main cold water inlet.

2. Install the pump near the water heater using union fittings for easy removal. Mount horizontally with the motor shaft level; vertical mounting reduces efficiency. Use stainless steel straps to secure to framing.

3. Connect the pump outlet to the return line using ¾-inch copper or PEX with crimp rings. Include a shut-off valve on both inlet and outlet for isolation.

4. Wire the pump to a timer or thermostat controller. Use 14/2 NM-B cable from a dedicated 15-amp circuit. Connect black (hot), white (neutral), and ground wires per NEC Article 422. Ground all metal components.

5. Set the thermostat or timer based on household usage. Program timers to run 30 minutes before morning and evening routines.

6. Pressurize the system and check for leaks. Open valves slowly. Power on and verify pump rotation (arrow on housing).

7. Test hot water delivery at the farthest fixture—should reach 105°F within 5 seconds.

For a crossover system:

1. Locate the farthest fixture from the water heater—usually a bathroom sink.

2. Install a thermostatic crossover valve under the sink, connecting hot and cold lines. Ensure cold water outlet feeds back into the hot water line.

3. Mount the pump at the water heater on the hot water outlet.

4. Wire to a thermostat sensor placed on the return pipe near the heater. Set activation temperature to 95–100°F.

5. Test for crossover flow by opening the hot tap briefly. Cold water may warm slightly—this is normal.

Demand systems add a push-button or motion sensor. Wire the switch to the pump relay per manufacturer instructions. Place sensors in high-traffic areas like master bathrooms.

Always comply with local plumbing codes. The Uniform Plumbing Code (UPC) Section 607 requires recirculation systems to include shut-off valves, thermal expansion tanks if present, and insulation on all hot water piping. Use R-3 or higher pipe insulation to reduce heat loss.

How Much Does a Water Heater Circulation Pump Cost?

Total installed cost for a water heater circulation pump ranges from $300 to $1,800, depending on system type, labor rates, and home configuration. Equipment alone costs $150–$500; labor adds $150–$1,300 based on complexity.

Demand-initiated systems cost $400–$800 installed. The Grundfos COMFORT PM D2 model retails for $350–$450. Labor: $150–$300 for electricians and plumbers to run low-voltage wiring and mount the pump. These systems save $50–$120 annually in water and energy, offering payback in 3–7 years.

Crossover systems cost $500–$900 installed. The Taco D’MAND D2 pump ($280–$360) pairs with a thermostatic valve ($80–$120). Labor: $200–$400 for mounting, sensor placement, and wiring. Ideal for retrofitting without structural changes.

Full-loop systems cost $800–$1,800 installed. Equipment: $300–$600 for pump, valves, and controls. Labor: $500–$1,200 due to running a ¾-inch return line through walls or floors. Costs double in multi-story homes or concrete slabs. New construction adds only $200–$400 since labor is already on-site.

Regional labor rates affect pricing: $65–$85/hour in the Midwest, $95–$130/hour in California and Northeast. Electricians charge $80–$110/hour for control wiring. Union contractors may charge 20–30% more but offer better warranties.

Tankless-compatible pumps cost 15–25% more than standard models due to precision flow control. Heat pump water heater retrofits may require additional check valves to prevent backflow into the condensate line.

DIY savings: $200–$600, but improper installation risks leaks, electrical hazards, or voided water heater warranties. Most manufacturers require certified installation for warranty validity.

Grundfos systems are available at Home Depot, while Taco pumps are sold at Lowe’s.

What Problems Might You Encounter with a Water Heater Circulation Pump?

Common circulation pump issues include noise, overheating, short cycling, warm cold water, and electrical faults—each linked to installation errors, component failure, or improper controls.

Noisy operation (grinding, humming, or vibrating) indicates air in the system, loose mounting, or worn bearings. Air locks form when the system isn’t properly bled. Open the pump’s bleed screw slowly until water flows steadily. Secure mounting brackets and use rubber isolation pads to reduce vibration transmission to walls.

Short cycling—frequent on/off cycling—occurs when the thermostat sensor is poorly placed or set too tight. Mount the sensor on the return line, not the heater jacket. Set differential to 5–10°F. For demand systems, ensure the timer allows 10–15 minutes between cycles to clear the line.

Warm cold water happens in crossover systems when the thermostatic valve leaks or activates too frequently. Install a check valve in the cold water line to prevent backflow. Set activation temperature to 98°F minimum. In summer, disable the pump if cold water exceeds 85°F at taps.

Overheating at fixtures occurs if the pump runs continuously without a timer or sensor. Install a programmable timer set to off during low-usage hours. Check for stuck relays or failed thermostats. Use a digital thermometer to verify delivery temperature—should not exceed 120°F at taps.

Electrical faults include tripped breakers or non-starting motors. Verify voltage at the junction box (120V ±5%). Check for loose wires, corroded connections, or failed capacitors. Use a multimeter to test continuity. Replace pumps with motors drawing over 1.5 amps under load.

Leakage at connections results from over-tightened fittings or incompatible materials. Use Teflon tape on threads and flux for solder joints. For PEX, ensure crimp rings are properly sized and inspected with go/no-go gauges.

Pump lifespan averages 8–12 years. Failure signs include reduced flow, erratic operation, or complete silence. Keep spare seals and impellers on hand for quick repairs.

How Do You Maintain and Troubleshoot a Water Heater Circulation Pump?

Annual maintenance extends pump life and ensures efficiency. Key tasks include inspecting for leaks, testing flow, cleaning strainers, verifying controls, and checking insulation.

Inspect for leaks at pump unions, valves, and pipe joints. Tighten connections only ¼ turn past hand-tight. Replace worn gaskets or O-rings.

Test flow rate using a bucket and stopwatch. Open a tap at the end of the loop and time how long it takes to fill a 1-gallon container. Flow should be 1–3 GPM. Low flow indicates clogged filters, air locks, or impeller damage.

Clean the inlet strainer every 6–12 months. Shut off power and water, open the strainer cap, and remove debris like sand or scale. Reassemble and bleed air.

Verify control settings seasonally. Adjust thermostat setpoints: 95°F in winter, 100°F in summer. Reprogram timers to match changing household schedules.

Check pipe insulation for damage. Replace crushed or moisture-soaked sections. Insulation reduces heat loss by 25–40%, lowering pump runtime.

Lubricate motor bearings only if specified by the manufacturer. Most modern pumps are sealed and require no lubrication.

Troubleshooting decision tree:

- Pump doesn’t start? → Check power (breaker, wiring), test voltage, inspect capacitor.

- Pump runs but no hot water? → Bleed air, verify flow direction, check for closed valves.

- Noisy pump? → Tighten mounts, bleed air, inspect for cavitation.

- Warm cold water? → Install check valve, adjust thermostat, inspect crossover valve.

- High energy use? → Install timer, insulate pipes, reduce runtime.

Keep a log of maintenance dates, flow tests, and repairs. This helps diagnose recurring issues and supports warranty claims.

Can a Circulation Pump Work with Tankless or Heat Pump Water Heaters?

Yes, circulation pumps work with tankless and heat pump water heaters if properly configured. Compatibility depends on flow requirements, control integration, and installation method.

Tankless water heaters require a minimum flow rate (0.5–0.7 GPM) to activate. Standard pumps may not generate enough flow, causing short cycling. Use tankless-specific recirculation pumps like the Grundfos COMFORT PM or Taco D’MAND that maintain 0.8–1.2 GPM. These models include buffer tanks or intelligent flow control to prevent rapid on/off cycling.

Install a dedicated return line or crossover valve. Without it, the tankless unit may not detect flow. For crossover systems, ensure the thermostatic valve allows sufficient backflow to trigger ignition.

Heat pump water heaters (HPWHs) like the AO Smith Voltex or Rheem RTE can use recirculation pumps but require caution. The compressor cycle generates condensate that must drain properly. Excessive recirculation can raise ambient temperature around the unit, reducing efficiency. Use low-speed pumps (under 20 watts) and insulate all hot water lines to minimize heat loss.

Avoid running the pump during HPWH’s heating mode if it causes temperature interference. Use a delay relay to prevent simultaneous operation.

Both systems benefit from demand-controlled pumps to minimize runtime. Smart controls like the Sensi or Honeywell Home can integrate with home automation for optimized scheduling.

What Safety and Code Requirements Apply to Circulation Pumps?

Circulation pumps must comply with electrical, plumbing, and mechanical codes to ensure safe operation. Key standards include NEC Article 422, UPC Section 607, and ASHRAE 90.1 energy efficiency requirements.

Electrical safety: Pumps must connect to a dedicated 15-amp circuit with GFCI protection if within 6 feet of a water source (NEC 210.8). Use conduit or NM-B cable rated for damp locations. All junction boxes must be accessible and labeled.

Plumbing safety: Include shut-off valves on both sides of the pump for isolation. Install a thermal expansion tank if the home has a check valve or pressure-reducing valve to prevent over-pressurization.

Scald protection: Hot water at fixtures must not exceed 120°F. Install thermostatic mixing valves at showers and tubs. UPC requires anti-scald devices in new construction.

Pipe insulation: All hot water piping must be insulated to R-3 or higher per IECC 2021. Uninsulated pipes lose 1–2°F per foot per minute, increasing pump runtime.

Clearances: Maintain 18 inches of clearance around the water heater and pump for servicing. Do not install pumps above gas water heaters where condensation could drip into the burner compartment.

Permit requirements vary by jurisdiction. Most cities require plumbing and electrical permits for recirculation system installation. Inspections verify compliance with local amendments to UPC and NEC.

FAQ

#### What are the best brands for water heater circulation pumps?

Grundfos, Taco, and Uponor are top brands for reliability and efficiency. Grundfos COMFORT models lead in smart controls and energy savings. Taco D’MAND series offers excellent value and tankless compatibility. Uponor’s Wirsbo pump integrates with radiant floor systems. All meet DOE and ASHRAE standards. Choose based on control type: Grundfos for demand systems, Taco for thermostatic, Uponor for hybrid setups. Each offers 5–7 year warranties with registered installation.

#### How much water and energy do circulation pumps save?

Recirculation pumps save 10,000–15,000 gallons of water annually in a four-person household by eliminating tap runoff. Energy savings range from 8–15% when paired with pipe insulation and timers. Demand systems save up to 30% more than continuous pumps by reducing runtime. Annual electricity cost is $15–$40 for 40-watt pumps running 4–6 hours daily. ROI occurs in 3–7 years depending on local water and energy rates.

#### Is a permit required to install a circulation pump?

Yes, most jurisdictions require plumbing and electrical permits. The Uniform Plumbing Code (UPC) and National Electrical Code (NEC) mandate inspections for system safety. Permits ensure compliance with shut-off valves, wiring methods, and insulation standards. Unpermitted work may void insurance or fail home inspections. Contact your local building department before installation. Fees range from $50–$150 depending on scope.

#### Can I install a circulation pump myself?

DIY installation is possible for experienced homeowners with plumbing and electrical skills. Tasks include soldering pipes, running electrical circuits, and programming controls. Mistakes can cause leaks, electrical shock, or water damage. Most manufacturers recommend professional installation to maintain warranty. If DIY, follow all code requirements and obtain permits. Consider hiring a plumber for piping and electrician for wiring.

#### How long do water heater circulation pumps last?

Most pumps last 8–12 years with annual maintenance. Failure rates increase after 10 years due to seal degradation and motor wear. Tankless-compatible models may last longer due to lower duty cycles. Signs of failure include noise, reduced flow, or failure to start. Keep spare parts like strainers and capacitors. Register your pump for extended warranty—Grundfos offers up to 7 years with registration.

#### Should the pump run 24/7 or on a schedule?

Pumps should not run 24/7 due to energy waste and pipe wear. Use a timer or demand control to limit operation to 4–6 hours daily—typically morning and evening. Continuous operation increases energy use by 2–3 times. Smart controllers learn usage patterns and adjust automatically. In vacation homes, disable the pump entirely.

#### Do I need a return line for recirculation?

A dedicated return line is ideal but not mandatory. Homes without return lines use crossover valves under the farthest sink to allow hot water to backflow into the cold line. This method is cheaper to install but can warm cold water slightly. Return lines maintain full temperature separation and are required in commercial buildings and some local codes.

#### What size pump do I need for my home?

Pump size depends on pipe length, diameter, and elevation. For homes under 2,500 sq ft with 100 feet of piping, a 3–5 foot head pump suffices. Use the formula: (Pipe length ÷ 100) × 1.5 = minimum head. Add 1 foot per story. Flow rate should be 1–3 GPM. Consult manufacturer performance charts—Grundfos and Taco provide online sizing tools. Oversizing causes noise and erosion.

A water heater circulation pump significantly improves convenience and sustainability by delivering instant hot water. Key decisions include choosing between full-loop, crossover, or demand systems, ensuring compatibility with your water heater type, and following code-compliant installation. Proper sizing, insulation, and controls maximize efficiency and longevity. Maintenance every 6–12 months prevents failures and ensures optimal performance. With professional installation and smart controls, recirculation systems offer a 3–7 year payback and long-term comfort benefits.