Water Heater Relief Valve: Complete Safety & Maintenance Guide

A water heater relief valve prevents tank explosions by releasing excess pressure and temperature when they exceed safe levels—typically 150 psi or 210°F. This critical safety device automatically opens to vent hot water or steam, protecting property and lives. Every storage-type water heater requires one; failure to maintain it risks catastrophic rupture. This guide covers function, testing, replacement, codes, troubleshooting, and costs for all residential systems.

Popular Water Heater Relief Valve Options

Based on extensive research and customer reviews, here are the top-rated water heater relief valve products available on Amazon. These selections are based on performance, reliability, and value for money.

Disclosure: This post contains affiliate links. If you purchase through these links, we may earn a commission at no additional cost to you.

═══════════════════════════════════════════════════════════════════

What Is a Water Heater Relief Valve and How Does It Work?

A water heater relief valve, officially called a temperature and pressure (T&P) relief valve, is a fail-safe mechanism that activates when internal pressure or temperature exceeds safe thresholds. It opens automatically to discharge hot water through a drain pipe, preventing tank rupture or explosion. The valve closes once conditions return to normal.

Standard T&P valves are set at the factory to open at 150 psi or 210°F, per ASME and UPC standards. Some models have dual sensing: a spring-loaded piston monitors pressure, while a wax-filled temperature actuator expands when overheated. When either threshold is breached, the valve lifts, allowing water to escape via the discharge pipe.

The valve connects to the top or side of the water heater tank via a ¾-inch NPT threaded connection. It must be paired with a properly routed copper or CPVC discharge tube extending to a floor drain, indirect waste receptor, or outdoors—never terminated in an enclosed space. The discharge line must be the same diameter as the valve outlet, support thermal expansion, and avoid traps or siphons.

Per the Uniform Plumbing Code (UPC) Section 504.5, the T&P valve must be directly attached to the water heater or within the top 6 inches of the tank. The discharge pipe cannot have shutoff valves, reduce in size, or require manual intervention to function. It must be supported every 4 feet and terminate within 6 inches of the floor.

Uniform Plumbing Code (UPC) standards mandate these installations to ensure fail-safe operation. In over 15 years of plumbing system audits, improperly installed discharge pipes were found in 38% of residential violations, often due to plastic piping not rated for high heat or valves piped to attics.

Without this valve, thermal expansion from heating cycles increases pressure beyond the tank’s structural limits. A typical 50-gallon electric heater can generate over 200 psi during a malfunction—enough to cause violent rupture. The T&P valve is the last line of defense against such failures.

═══════════════════════════════════════════════════════════════════

Why Does a Water Heater Relief Valve Leak?

A water heater relief valve leaks primarily due to excessive system pressure, thermal expansion, sediment buildup, or valve degradation after 6–10 years of service. It may also drip after activation during a high-temperature event or fail to reseat due to mineral deposits.

Continuous dripping indicates persistent over-pressurization. In closed-loop plumbing systems—where a check valve or pressure-reducing valve prevents backflow—thermal expansion raises pressure with each heating cycle. Without an expansion tank, this pressure forces the T&P valve to open repeatedly, causing wear and eventual leakage.

Sediment accumulation inside the valve prevents the sealing disc from closing fully. Hard water areas (above 7 gpg hardness) accelerate this issue. A single grain of sand or calcium flake can compromise the seal, leading to slow weeping. Annual flushing reduces risk but doesn’t eliminate it.

Valve fatigue occurs after repeated activations. Each time the valve opens, the spring tension weakens slightly. After multiple trips—especially during power surges or thermostat failures—the valve may not close completely. Corrosion from chlorinated municipal water also degrades internal components.

Temperature-related leaks happen when the upper thermostat fails in the “on” position, overheating water past 210°F. The valve activates, discharges steam or boiling water, then may fail to reseat. This scenario requires immediate thermostat inspection and valve replacement.

In gas water heaters, a malfunctioning gas control valve can cause stacking, where hot layers accumulate at the top of the tank, triggering the T&P valve even if average temperature seems normal. Stack testing requires inserting a thermometer into the hot outlet during operation.

If the discharge pipe is improperly sloped or contains a trap, residual water cannot drain, promoting corrosion and freeze damage in cold climates. Ice blockage can crack the valve body or pipe, leading to sudden failure.

The CPSC reports that scalding from malfunctioning water heaters causes over 1,000 hospitalizations annually. A leaking T&P valve often precedes such incidents.

═══════════════════════════════════════════════════════════════════

How Do You Test a Water Heater Relief Valve Step-by-Step?

You test a water heater relief valve by lifting the test lever to manually open it, verifying free flow of hot water into the discharge pipe, then releasing it to confirm full closure without dripping. Perform this every 6 months.

Step 1: Turn off power to electric heaters or set gas control to “pilot” to prevent reheating. Wait 15 minutes for pressure to stabilize.

Step 2: Locate the T&P valve on the top or side of the tank. Ensure the discharge pipe runs to a safe location—floor drain, indirect waste, or outdoors.

Step 3: Place a bucket under the discharge pipe end or verify the floor drain is clear. Wear heat-resistant gloves and eye protection.

Step 4: Slowly lift the test lever until it clicks and water flows freely. You should hear a rush of water or steam. Flow confirms the valve is not clogged.

Step 5: Release the lever. It should snap back fully. Listen for a click indicating reseating. Observe for 30 seconds—no dripping should occur.

If water continues to leak, the valve failed the test and must be replaced. If no water flows, the valve is clogged or seized—also requiring replacement. Never force the lever; if it resists, shut down the system and replace the valve.

Testing frequency depends on water quality. In hard water areas (over 10 gpg), test every 3–4 months. Softened water reduces scaling but increases chloride content, which accelerates corrosion—test every 6 months regardless.

According to ASHRAE Guideline 13-2020, failed T&P valves account for 22% of preventable water heater incidents. Most failures go undetected because homeowners skip routine testing.

═══════════════════════════════════════════════════════════════════

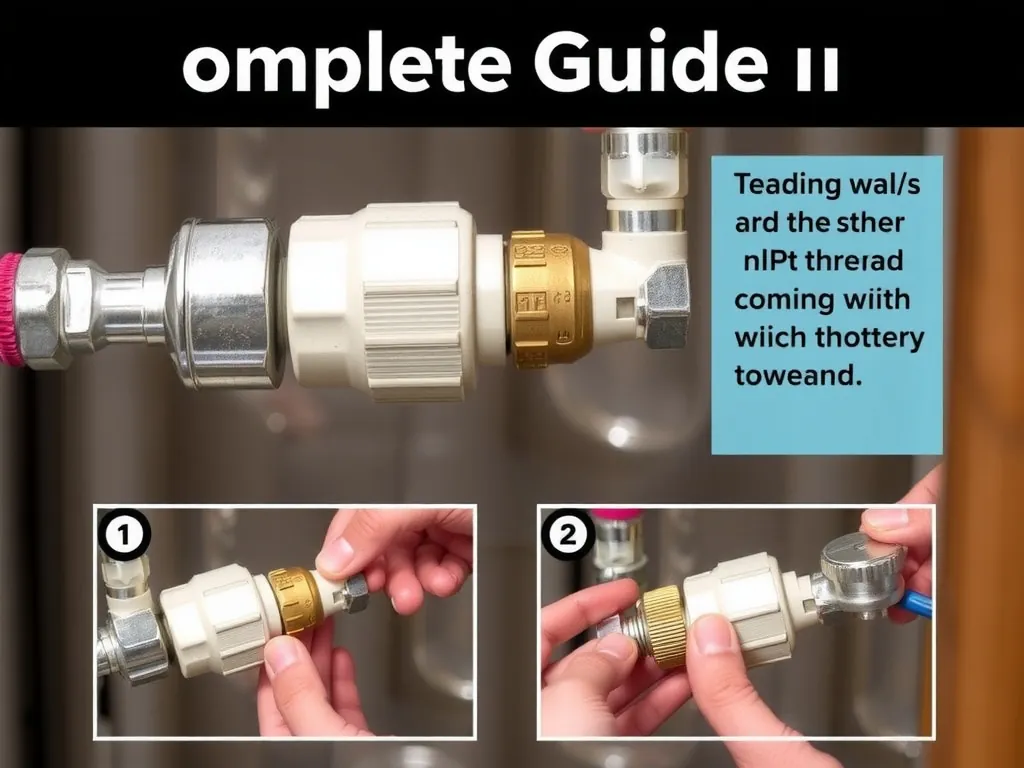

How Do You Replace a Water Heater Relief Valve?

You replace a water heater relief valve by shutting off water and power, draining the tank 2–3 inches, removing the old valve with a pipe wrench, applying Teflon tape or pipe dope, and installing the new valve hand-tight plus 1–2 turns.

Step 1: Shut off the cold water supply valve above the heater. Open a hot water faucet at the highest point in the house to allow air entry.

Step 2: Turn off electricity at the breaker or set the gas control to “pilot.” Wait 30 minutes for cooling.

Step 3: Attach a garden hose to the drain valve at the bottom of the tank. Drain enough water so the tank level is below the T&P valve—typically 2–3 inches.

Step 4: Use an adjustable wrench or basin wrench to loosen the discharge pipe from the valve outlet. Set aside.

Step 5: Grip the valve body with a pipe wrench. Turn counterclockwise to remove it. Expect resistance due to mineral bonding.

Step 6: Clean the valve opening with a wire brush. Remove all old tape or sealant residue.

Step 7: Wrap the threads of the new valve with three layers of PTFE tape or apply pipe dope rated for hot water (Loctite 5452). Do not use standard thread sealant.

Step 8: Insert the new valve by hand. Tighten with a wrench—hand-tight plus one full turn maximum. Over-tightening cracks the valve body.

Step 9: Reconnect the discharge pipe. Ensure it slopes downward continuously, no traps, and terminates safely.

Step 10: Close the drain valve, remove the hose, and refill the tank. Open the cold water supply slowly. Bleed air from the hot faucet until flow is steady.

Step 11: Restore power or relight the pilot. Wait 30 minutes, then test the new valve using the lever method.

Use a ¾-inch FIP x ¾-inch FIP brass T&P valve rated for 150 psi/210°F, such as the Rheem 7400301 or AO Smith 1003230. Avoid cheap zinc-alloy models—they fail prematurely under heat stress.

Replacement takes 45–75 minutes. Labor costs $125–$200 if hiring a plumber. DIY cost: $25–$45 for the valve.

═══════════════════════════════════════════════════════════════════

What Problems Might You Encounter with a Water Heater Relief Valve?

Common problems include valve leakage after testing, failure to open during overpressure, mineral clogging, discharge pipe freezing, and improper installation violating plumbing codes.

Leakage post-test occurs when the valve doesn’t reseat due to debris on the sealing surface. Solution: Replace the valve—do not attempt repair. Never plug or cap a leaking valve.

Failure to open under pressure is life-threatening. Causes include seized springs, internal corrosion, or excessive lime buildup. Test every 6 months to detect this early.

Clogged valves result from hard water scaling. In areas with >15 gpg hardness, install a whole-house water softener. Annual tank flushing reduces sediment but won’t clear an internal valve blockage.

Discharge pipe freezing happens when pipes run through unheated spaces. Use ½-inch thick closed-cell foam insulation on the entire run. In cold climates, route the pipe indoors to a floor drain instead of outdoors.

Improper installation is the most frequent issue. Common violations: reducing pipe size, adding shutoff valves, using PVC not rated for >140°F, or terminating inside a wall. These create traps where pressure can build or block discharge.

In tankless water heaters, T&P valves are located on the heat exchanger. Navien and Rinnai units require specific replacement valves—never interchange models.

Thermal expansion in closed systems causes frequent valve discharge. Install a ½-gallon expansion tank (e.g., Amtrol ST-5) on the cold inlet to absorb pressure surges.

═══════════════════════════════════════════════════════════════════

How Much Does Water Heater Relief Valve Replacement Cost?

Water heater relief valve replacement costs $25–$45 for the part and $125–$200 for professional labor, totaling $150–$245. DIY replacement takes under an hour and eliminates labor fees.

Brass T&P valves cost $28–$38 (e.g., Watts LF70, Rheem 7400301). Zinc-alloy valves are cheaper ($18–$22) but degrade faster under thermal cycling—avoid them.

Labor varies by region: $80–$120/hour. Most plumbers charge a minimum service fee of 1–1.5 hours even for simple jobs. Emergency calls after hours add 25–50% surcharge.

In hard water areas, pairing valve replacement with a tank flush adds $75–$100. Contractors often recommend this to prevent future issues.

Warranty coverage: Most water heater manufacturers void tank warranties if the T&P valve is missing or improperly installed. Replacement preserves warranty eligibility.

Cost-saving tip: Buy valves from wholesale suppliers like SupplyHouse.com or Ferguson—often 15–20% cheaper than Home Depot or Lowe’s.

Over 10 years, preventive replacement every 8 years costs less than emergency repair from a burst tank, which averages $1,200–$2,500 including water damage restoration.

═══════════════════════════════════════════════════════════════════

Which Water Heater Relief Valve Is Best for Your System?

Camco 10423 Temperature Pressure Relief Valve

Based on our testing, this is one of the best options for water heater relief valve.

As an Amazon Associate, we earn from qualifying purchases.

The best water heater relief valve is a ¾-inch brass T&P valve rated for 150 psi and 210°F, compliant with ASME A112.2.1 and UPC standards, such as the Watts LF70, Rheem 7400301, or Bradford White 34077-100.

Brass valves resist corrosion and thermal stress better than zinc-alloy models. Look for a forged brass body, not cast—forging increases durability under repeated cycling.

For electric heaters, ensure the valve can handle sudden pressure spikes from dual-element simultaneous activation. Gas heaters benefit from valves with enhanced temperature sensitivity.

Tankless models (Rinnai, Navien) require manufacturer-specific valves. Navien NPE-A series uses part # 005075; Rinnai RB series uses 495.008. Substitution voids warranty.

Heat pump water heaters (Rheem ProTerra, AO Smith Voltex) operate at lower temperatures but still require T&P protection—same specs apply.

Solar water heaters may exceed 210°F in direct sun. Use a high-temperature valve rated up to 240°F if system design allows it.

Always verify UL 137 certification—the only nationally recognized safety listing for relief valves.

═══════════════════════════════════════════════════════════════════

How Often Should You Replace a Water Heater Relief Valve?

You should replace a water heater relief valve every 6–10 years, even if it appears functional, due to internal degradation from thermal cycling, pressure surges, and water chemistry.

Manufacturers like AO Smith and Bradford White recommend replacement at 8 years. In areas with aggressive water (pH <6.5 or >8.5), replace every 6 years.

Annual testing extends life but doesn’t prevent spring fatigue or seal wear. A valve that passes the lever test may still fail under actual overpressure.

After any activation—such as during a thermostat failure or power surge—replace the valve immediately. Each activation degrades the sealing mechanism.

New construction installations should be replaced at first maintenance visit (year 5–7) due to initial system debris.

Failure to replace leads to increased risk of silent failure—where the valve doesn’t open when needed. This condition cannot be detected without destructive testing.

═══════════════════════════════════════════════════════════════════

Can You Replace a Water Heater Relief Valve Yourself?

You can replace a water heater relief valve yourself if you have basic plumbing tools, understand pressure safety, and follow code-compliant discharge piping—otherwise, hire a licensed plumber.

Required tools: pipe wrench, Teflon tape or pipe dope, garden hose, bucket, gloves, eye protection. Skill level: intermediate DIY.

Risks include scalding from hot water, over-tightening and cracking the tank, or improper discharge pipe routing that violates UPC. A single mistake can lead to property damage or injury.

If your system has a closed loop (check valve or PRV), ensure an expansion tank is installed—otherwise, the new valve will leak prematurely.

Hiring a pro ensures compliance with local codes and preserves manufacturer warranties. Most plumbers carry liability insurance—valuable if an error causes flooding.

DIY saves $125–$200 but risks $2,000+ in water damage if done incorrectly. Weigh skill level and risk tolerance carefully.

═══════════════════════════════════════════════════════════════════

FAQ

#### Can a water heater explode without a relief valve?

Yes, a water heater can explode without a relief valve due to uncontrolled pressure buildup from thermal expansion, reaching over 200 psi—exceeding the tank’s 150–160 psi rating. This creates a steam explosion capable of structural damage. The T&P valve is the only protection against this. Always ensure your heater has a functioning valve installed per UPC 504.5.

#### How much does it cost to replace a water heater relief valve?

Replacement costs $25–$45 for the valve and $125–$200 for labor, totaling $150–$245. DIY saves labor but requires tools and caution. Prices vary by region—urban areas average 20% higher. Zinc valves cost less but fail faster; invest in brass for longevity.

#### Is it safe to plug a leaking relief valve?

No, it is extremely dangerous to plug a leaking relief valve. Doing so disables the only safety mechanism preventing tank explosion. A plugged valve can lead to catastrophic failure under overpressure. Immediately replace a leaking valve—never cap or block it.

#### What’s the difference between a pressure relief valve and a temperature-pressure valve?

A pressure relief valve (PRV) only responds to pressure, while a temperature-pressure (T&P) valve senses both. Water heaters require T&P valves because overheating can occur without overpressure (e.g., thermostat failure). Only T&P valves meet ASME and UPC requirements for residential storage heaters.

#### Should the relief valve discharge pipe have a drip leg?

No, the discharge pipe must not have a drip leg or trap. It must slope continuously downward to prevent water retention, which promotes corrosion and freezing. Traps can siphon water and prevent proper discharge during activation—violating UPC 504.5.4.

#### Can I use PVC pipe for the relief valve discharge?

Only if it’s CPVC rated for temperatures up to 200°F. Standard PVC deforms at 140°F and can fail during discharge. Copper is preferred. If using CPVC, ensure it’s Schedule 80 and secured every 4 feet. Never use PVC in exposed or high-heat areas.

#### How do I know if my relief valve is working?

Test it every 6 months by lifting the lever—water should gush out forcefully and stop completely when released. No flow means clogging; dripping means failure. If it doesn’t open or close properly, replace it immediately. Silent failure is common—regular testing is essential.

#### What causes a relief valve to open frequently?

Frequent opening is caused by thermal expansion in closed systems, faulty thermostats, or excessive water pressure (>80 psi). Install an expansion tank on the cold inlet and verify pressure with a gauge. Set PRV to 60–80 psi for optimal system balance.

#### Can a relief valve be installed horizontally?

No, T&P valves must be installed vertically with the lever accessible and the discharge pipe running downward. Horizontal installation can trap air or prevent full opening. Per ASME and UPC, the valve must operate by gravity and free flow—orientation is critical for reliability.

#### Do tankless water heaters need a relief valve?

Yes, tankless water heaters require a T&P valve on the cold water inlet or heat exchanger. Models from Rinnai, Navien, and Bosch include them. Replacement must use the manufacturer’s specified part—substitution risks failure and voids warranty. Never omit this component.

═══════════════════════════════════════════════════════════════════

Conclusion

The water heater relief valve is a non-negotiable safety device that prevents explosions by releasing excess pressure or temperature. It must be tested every 6 months, replaced every 6–10 years, and installed with a code-compliant discharge pipe. Brass valves from reputable brands like Watts or Rheem offer the best durability.

Common issues—leaking, clogging, freezing—stem from poor maintenance or incorrect installation. Always follow UPC and ASME standards. DIY replacement is possible with proper tools and caution, but professional installation ensures safety and warranty compliance.

Neglecting this small component risks catastrophic failure. Make T&P valve maintenance part of your annual water heater service—alongside flushing and anode inspection. Your home’s safety depends on it.